FREQUENTLY ASKED QUESTIONS - F.A.Q.

For most people in India, mattresses means cotton mattresses!

Still others may say, "Aren't they all the same? What difference does it make?"

However, there are different kinds of mattresses available in the market.

Latex Foam, Polyurethane, Coir and Spring are the popular kinds. There also are composite mattresses available, which are made by mixing and matching these materials. Water and air beds can also be considered as variants.

Since we spend about one-third of our life on mattresses and a big part of the remaining time on some kind of a cushioning material, it is important to know more about these options so as to make a wise decision. After all, we live only once!

Still others may say, "Aren't they all the same? What difference does it make?"

However, there are different kinds of mattresses available in the market.

Latex Foam, Polyurethane, Coir and Spring are the popular kinds. There also are composite mattresses available, which are made by mixing and matching these materials. Water and air beds can also be considered as variants.

Since we spend about one-third of our life on mattresses and a big part of the remaining time on some kind of a cushioning material, it is important to know more about these options so as to make a wise decision. After all, we live only once!

When it comes to mattresses, there are many options available in the market. To get a detailed comparison of the various mattress options, click here.

We recommend you however, to TEST SLEEP your mattress before you take the call.

How to TEST SLEEP?

The recommended steps for a TEST SLEEP could be considered as follows:

Step 1. Shortlist a few mattresses from the options available at a retailer

Step 2. Lie down on the several different models in various positions

Step 3. Try the position that you usually sleep in for a slightly longer time

Step 4. Take a few extra minutes for focusing on the “feel”

Step 5. Evaluate the mattress both on the comfort and the support*

Step 6. Partners should Test Sleep together

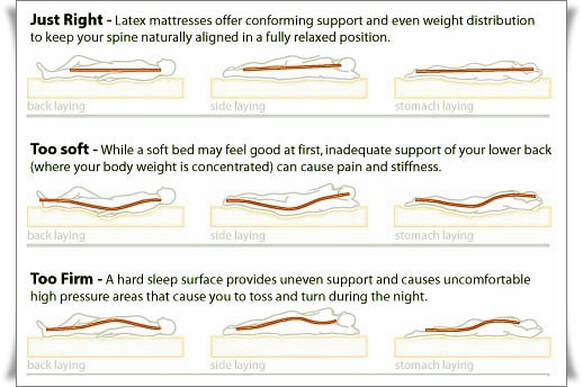

While different kinds of mattresses might be suitable for different people, generally, it has been found worldwide that latex foam mattresses suits everyone! Latex Foam mattresses, for a given size and thickness are the most expensive among the different commercially available options. However, they provide the best orthopedic support and most luxurious comfort - the necessary ingredients for good night’s rest and fresh mornings.

We recommend you however, to TEST SLEEP your mattress before you take the call.

How to TEST SLEEP?

The recommended steps for a TEST SLEEP could be considered as follows:

Step 1. Shortlist a few mattresses from the options available at a retailer

Step 2. Lie down on the several different models in various positions

Step 3. Try the position that you usually sleep in for a slightly longer time

Step 4. Take a few extra minutes for focusing on the “feel”

Step 5. Evaluate the mattress both on the comfort and the support*

Step 6. Partners should Test Sleep together

While different kinds of mattresses might be suitable for different people, generally, it has been found worldwide that latex foam mattresses suits everyone! Latex Foam mattresses, for a given size and thickness are the most expensive among the different commercially available options. However, they provide the best orthopedic support and most luxurious comfort - the necessary ingredients for good night’s rest and fresh mornings.

Latex Foam Mattresses are better than the mattresses made from any other substance, like, Polyurethane, Spring or Coir because of their superior cushioning and resilience. They provide deep orthopedic support to the spine while also providing lush and luxurious comfort.

Germans consider LatexFoam as the Mercedes Benz and the BMW of the mattresses. However, just as for Mercedes Benz and BMW, there are several substitutes to Latex Foam too in the market.

SUBSTITUTE 1

Polyurethane Foam (a.k.a. PU Foam/U-foam):

This is the most popular and most widely used of all the substitutes to Latex Foam. It claims of admirable properties like durability (with regards to size and shape), light weight, wash-ability, enhanced workability and most importantly low price.

However, there are two major drawbacks to this product.

First, it loses its resilience very soon and so it becomes ineffective in the very purpose for which it is used. It usually doesn’t lose shape but it becomes very fluffy and soft.

Second, it is a bio-toxic and thus environmentally non-friendly product. This is one reason why a growing number of countries have banned the production of PU Foam.

SUBSTITUTE 2

Coir:

Coir replaces LatexFoam mainly in the mattress segment. It is cheaper than latex foam and firmer than polyurethane foam. However, its popularity is very quickly waning.

It is still only a modified and well-presented version of the old Indian doormat. It is an aggregate of fibers stuck together with the help of Natural Latex. If it is of a good quality, it sags in a couple of years and loses its utility. Most of the coir available in the market today, sags within 2 years. This is the reason why no coir mattress manufacturer gives a guarantee of more than two years.

SUBSTITUTE 3

Spring:

Thousands of steel springs are held together by more steel wires and padded with U-foam and/or coir to replicate the cushioning effect provided by LatexFoam. Some manufacturers have succeeded in giving the market a good product, but in the process, they have managed to provide a product more costlier than latex foam.

Moreover, the thousands of springs still fall short of the uniform support that millions of rubber molecules in the lattices of Latex Foam provide. Latex Foam is equivalent to millions of molecular springs working in unison to support the body. The pressure exerted back on the body is much lower than any other kind of mattress. This helps in better blood circulation during sleep and therefore fresh mornings, without body aches.

One major draw back of spring mattresses is that it transfers the movements across its surface thus disturbing the other partner. Other complaints include sagging, squeaking noises and loss of resilience.

SUBSTITUTE 4

Cotton:

It is the most commonly used cushion in India as it is the cheapest and easily available. However, it has been found to be unhygienic, does not provide uniform support and preferably should not be used by several users as it accumulates perspiration and body salts etc.

Germans consider LatexFoam as the Mercedes Benz and the BMW of the mattresses. However, just as for Mercedes Benz and BMW, there are several substitutes to Latex Foam too in the market.

SUBSTITUTE 1

Polyurethane Foam (a.k.a. PU Foam/U-foam):

This is the most popular and most widely used of all the substitutes to Latex Foam. It claims of admirable properties like durability (with regards to size and shape), light weight, wash-ability, enhanced workability and most importantly low price.

However, there are two major drawbacks to this product.

First, it loses its resilience very soon and so it becomes ineffective in the very purpose for which it is used. It usually doesn’t lose shape but it becomes very fluffy and soft.

Second, it is a bio-toxic and thus environmentally non-friendly product. This is one reason why a growing number of countries have banned the production of PU Foam.

SUBSTITUTE 2

Coir:

Coir replaces LatexFoam mainly in the mattress segment. It is cheaper than latex foam and firmer than polyurethane foam. However, its popularity is very quickly waning.

It is still only a modified and well-presented version of the old Indian doormat. It is an aggregate of fibers stuck together with the help of Natural Latex. If it is of a good quality, it sags in a couple of years and loses its utility. Most of the coir available in the market today, sags within 2 years. This is the reason why no coir mattress manufacturer gives a guarantee of more than two years.

SUBSTITUTE 3

Spring:

Thousands of steel springs are held together by more steel wires and padded with U-foam and/or coir to replicate the cushioning effect provided by LatexFoam. Some manufacturers have succeeded in giving the market a good product, but in the process, they have managed to provide a product more costlier than latex foam.

Moreover, the thousands of springs still fall short of the uniform support that millions of rubber molecules in the lattices of Latex Foam provide. Latex Foam is equivalent to millions of molecular springs working in unison to support the body. The pressure exerted back on the body is much lower than any other kind of mattress. This helps in better blood circulation during sleep and therefore fresh mornings, without body aches.

One major draw back of spring mattresses is that it transfers the movements across its surface thus disturbing the other partner. Other complaints include sagging, squeaking noises and loss of resilience.

SUBSTITUTE 4

Cotton:

It is the most commonly used cushion in India as it is the cheapest and easily available. However, it has been found to be unhygienic, does not provide uniform support and preferably should not be used by several users as it accumulates perspiration and body salts etc.

Good quality latex foam, like ‘GeoFoam’, can easily last 10-12 years. A poor quality latex foam can collapse in as low as 6 months!

To bring the costs down, inferior latex foam manufacturers reduce the amount of latex used to make the latex foam. They load the foam with fillers which makes the foam feel firm. However, this reduces the strength, load bearing capacity and resilience of the latex foam.

‘GeoFoam’ offers a Seven-Year 'Performance Guarantee' on each of its products. The ‘Performance Guarantee’ means that our products will give the desired optimum performance throughout the period of guarantee. The mattresses or sofa cushions will support you and feel as good as new through the period of seven years. Considering the high ambient temperatures prevalent in India, this is a good offer.

To bring the costs down, inferior latex foam manufacturers reduce the amount of latex used to make the latex foam. They load the foam with fillers which makes the foam feel firm. However, this reduces the strength, load bearing capacity and resilience of the latex foam.

‘GeoFoam’ offers a Seven-Year 'Performance Guarantee' on each of its products. The ‘Performance Guarantee’ means that our products will give the desired optimum performance throughout the period of guarantee. The mattresses or sofa cushions will support you and feel as good as new through the period of seven years. Considering the high ambient temperatures prevalent in India, this is a good offer.

A good quality latex foam will neither crumble nor powder for over 10-12 years. The various reasons for such an occurrence is listed here.

Reason 1

Sunlight:

Exposure to sunlight accelerates the oxidation and therefore the ageing. So the product should be kept away from exposure to direct sunlight at all times! Sometimes people try to dry the mattress in the sun to dry off the wetness. However, such a action destroys the foam.

Reason 2

Poor Quality:

To reduce the cost, several latex foam manufacturers use less of latex and more of fillers. Such a product powders, crumbles, sags and collapses in a very short while. This is an unethical practice and is equivalent to cheating the customer by giving false hopes.

Reason 3

Age-ing:

Being 100% Natural, the Latex Foam is subject to ageing. For good quality latex foam, after over a decade of use, ageing starts affecting it. This is a characteristic of all natural substances. As a result of ageing, the latex foam starts losing its resilience and starts powdering too.

Reason 1

Sunlight:

Exposure to sunlight accelerates the oxidation and therefore the ageing. So the product should be kept away from exposure to direct sunlight at all times! Sometimes people try to dry the mattress in the sun to dry off the wetness. However, such a action destroys the foam.

Reason 2

Poor Quality:

To reduce the cost, several latex foam manufacturers use less of latex and more of fillers. Such a product powders, crumbles, sags and collapses in a very short while. This is an unethical practice and is equivalent to cheating the customer by giving false hopes.

Reason 3

Age-ing:

Being 100% Natural, the Latex Foam is subject to ageing. For good quality latex foam, after over a decade of use, ageing starts affecting it. This is a characteristic of all natural substances. As a result of ageing, the latex foam starts losing its resilience and starts powdering too.

'Latex Foam' is making a come back the world over.

The comeback of Latex Foam is happening mainly because of the 'Unparalleled Superior and Natural Orthopedic Support' that it offers, but more importantly, because of its 'Environmental Friendliness'. Latex foam is 'Bio-degradable' and therefore it is ‘Green”.

Latex Foam is the original mattress and cushioning product of the mass market. However, slowly, especially after the 90s, other substitutes started replacing it worldwide. Latex Foam started waning in popularity for a while. The reasons for this are manifold.

Limited RM Availability:

Natural Latex being available from the sap of the Rubber tree only, it was available only in certain countries like Brazil, Malaysia, Sri Lanka, India etc which have tropical climate. Procuring it from these countries was a costly affair and so all the developed countries developed alternative products. All these alternative products were not necessarily better products in terms of performance, but only better with regards to feasibility and availability.

Rising RM Costs:

The Latex prices, pushed by the increased demand for automobile tires, sky rocketed in the last decade pushing the prices of latex foam ahead of all alternatives in the market. For a product category like mattresses and cushions, which are usually procured only at the fag end of a purchasing spree for a new or renovated home, customers usually come up either with wafer thin budgets or after over-the-board expenditure and therefore usually settle for the cheapest alternatives.

Difficulty of Handling:

Latex foam is not easy to handle or display, be it at the showroom or at home. It’s not that people walk around with their mattresses, but homemakers sometimes prefer mattresses which are light weight, keeping in mind the convenience of dressing up and maintenance. Polyurethane made deep in-roads just because of the benefit of handling!

Limited by Technology:

There are two ways of manufacturing latex foam. Dunlop process, which we use and the Talalay process. Dunlop process is a batch process and can be operative at a small scale while, Talalay process is very capital intensive and large scale continuous process. Most latex foam manufacturers are in the small scale with limited potential (technologically) for widespread market capitalization. Meanwhile, the large scale process is too heavy on investments to promise a lucrative ROI. The substitute product processes however are not so heavy on investments and operate on either a low cost or high margin formula and therefore have promoters with good financial muscle power and branding strategies running them.

Compromised Quality:

A lot of manufacturers compromised the quality of their products for surviving in the market place. This resulted in the market being flooded with inferior latex foam. In a short while, latex foam had been tarnished. Even today, a lot of people who have burnt their fingers once look at the product with suspicion.

The comeback of Latex Foam is happening mainly because of the 'Unparalleled Superior and Natural Orthopedic Support' that it offers, but more importantly, because of its 'Environmental Friendliness'. Latex foam is 'Bio-degradable' and therefore it is ‘Green”.

Latex Foam is the original mattress and cushioning product of the mass market. However, slowly, especially after the 90s, other substitutes started replacing it worldwide. Latex Foam started waning in popularity for a while. The reasons for this are manifold.

Limited RM Availability:

Natural Latex being available from the sap of the Rubber tree only, it was available only in certain countries like Brazil, Malaysia, Sri Lanka, India etc which have tropical climate. Procuring it from these countries was a costly affair and so all the developed countries developed alternative products. All these alternative products were not necessarily better products in terms of performance, but only better with regards to feasibility and availability.

Rising RM Costs:

The Latex prices, pushed by the increased demand for automobile tires, sky rocketed in the last decade pushing the prices of latex foam ahead of all alternatives in the market. For a product category like mattresses and cushions, which are usually procured only at the fag end of a purchasing spree for a new or renovated home, customers usually come up either with wafer thin budgets or after over-the-board expenditure and therefore usually settle for the cheapest alternatives.

Difficulty of Handling:

Latex foam is not easy to handle or display, be it at the showroom or at home. It’s not that people walk around with their mattresses, but homemakers sometimes prefer mattresses which are light weight, keeping in mind the convenience of dressing up and maintenance. Polyurethane made deep in-roads just because of the benefit of handling!

Limited by Technology:

There are two ways of manufacturing latex foam. Dunlop process, which we use and the Talalay process. Dunlop process is a batch process and can be operative at a small scale while, Talalay process is very capital intensive and large scale continuous process. Most latex foam manufacturers are in the small scale with limited potential (technologically) for widespread market capitalization. Meanwhile, the large scale process is too heavy on investments to promise a lucrative ROI. The substitute product processes however are not so heavy on investments and operate on either a low cost or high margin formula and therefore have promoters with good financial muscle power and branding strategies running them.

Compromised Quality:

A lot of manufacturers compromised the quality of their products for surviving in the market place. This resulted in the market being flooded with inferior latex foam. In a short while, latex foam had been tarnished. Even today, a lot of people who have burnt their fingers once look at the product with suspicion.

Latex Foam is washable. During the manufacturing, it goes through a stage of washing. However, it has to be given a uniform drying which is not possible in a normal domestic setup, this making it qualify into the category of non-washable.

During the term of its usage, liquids will fall on to Latex Foam. Allowing it to drying normally will not hinder the performance of the Latex Foam. However, trying to dry it in the sunlight should be totally avoided.

During the term of its usage, liquids will fall on to Latex Foam. Allowing it to drying normally will not hinder the performance of the Latex Foam. However, trying to dry it in the sunlight should be totally avoided.

Latex Foam has a thick outer skin which inhibits the circulation of air. This thick skin aids the greater resilience and cushioning property of latex foam. However, this thick outer skin also allows a mild heat buildup in the foam. A similar degree of buildup happens in polyurethane foam too!

Using 100% cotton fabric as the mattress cover or using a cotton quilt as a mattress cover greatly reduces the impact of the mild heat build-up, if any.

If the ambient temperature of the room is controlled as in an air-conditioned room, such a concern becomes totally irrelevant! Since most people today have air-conditioned rooms, the concern raised by the way of this question is disqualified

Using 100% cotton fabric as the mattress cover or using a cotton quilt as a mattress cover greatly reduces the impact of the mild heat build-up, if any.

If the ambient temperature of the room is controlled as in an air-conditioned room, such a concern becomes totally irrelevant! Since most people today have air-conditioned rooms, the concern raised by the way of this question is disqualified

Latex Foam is characterized by cavities on either or both sides. Often, people identify the product due to these holes on the product.

These holes have multiple roles to play.

Surface Area:

They increase the surface of the foam. This aids greater breath-ability of the product, aids the drying (during and after the process), and dissipates the heat build up.

Cushioning:

The structure and position of the cavities improves the cushioning capability of the product.

Weight:

The cavities help reduce the weight of the product. This helps in the handling not only when it’s a final product but also during the stages of manufacturing.

Cost:

The cost is also marginally reduced because of the presence of the cavities on the foam.

These holes have multiple roles to play.

Surface Area:

They increase the surface of the foam. This aids greater breath-ability of the product, aids the drying (during and after the process), and dissipates the heat build up.

Cushioning:

The structure and position of the cavities improves the cushioning capability of the product.

Weight:

The cavities help reduce the weight of the product. This helps in the handling not only when it’s a final product but also during the stages of manufacturing.

Cost:

The cost is also marginally reduced because of the presence of the cavities on the foam.

Latex Foam is characterized by cavities on either or both sides. Often, people identify the product due to these holes on the product. The cavity sizes are different depending on the end application.

Different cavity sizes maybe used depending on the base chosen by the sofa manufacturers.

Wooden Base:

If the sofa base is wooden, the 17mm cavity sized cushions are a better option.

Spring & Belt Base:

However, more common sofa bases are the spring base and the elastic belt base. For these, the blocks with 6mm cavity size are more appropriate.

Different cavity sizes maybe used depending on the base chosen by the sofa manufacturers.

Wooden Base:

If the sofa base is wooden, the 17mm cavity sized cushions are a better option.

Spring & Belt Base:

However, more common sofa bases are the spring base and the elastic belt base. For these, the blocks with 6mm cavity size are more appropriate.

Coir mattresses are made by spraying latex on coconut fibers and compressing them. Coir is available cheaply and also, since the natural latex is only sprayed sparsely, the RM cost is not very high.

Polyurethane is made from petroleum based products. The prices of these have only gone upwards in last few years. However, polyurethane foam is made by blowing up the polyurethane mix by over 30-40times of its original volume to give products of 32-40 kg/cu.mtr. This makes the resultant foam economical.

Spring is made by making a structure of steel and then covering it appropriately with cloth. The cost of making it is almost equivalent to the weight of steel used in making a mattress plus the cost of fabrics used.

Latex Foam is made from Natural Latex which is also the ingredient for all the automobile tires made in the world and also used in several auto components. Owing to the bullish trend in the global auto market, latex and therefore rubber prices have sky-rocketed in the last decade. Though latex foam is made by foaming the latex to about 10 times of its original volume, the resultant foam is a uniform solid block with a density of 100kg/cu.mtr. Moreover, the batch process doesn’t allow economies of scale for a already pricey raw material. Owing to all these reasons, latex foam is costlier than its substitutes.

Polyurethane is made from petroleum based products. The prices of these have only gone upwards in last few years. However, polyurethane foam is made by blowing up the polyurethane mix by over 30-40times of its original volume to give products of 32-40 kg/cu.mtr. This makes the resultant foam economical.

Spring is made by making a structure of steel and then covering it appropriately with cloth. The cost of making it is almost equivalent to the weight of steel used in making a mattress plus the cost of fabrics used.

Latex Foam is made from Natural Latex which is also the ingredient for all the automobile tires made in the world and also used in several auto components. Owing to the bullish trend in the global auto market, latex and therefore rubber prices have sky-rocketed in the last decade. Though latex foam is made by foaming the latex to about 10 times of its original volume, the resultant foam is a uniform solid block with a density of 100kg/cu.mtr. Moreover, the batch process doesn’t allow economies of scale for a already pricey raw material. Owing to all these reasons, latex foam is costlier than its substitutes.

GeoFoam uses high Latex content to make its mattresses and cushions. Now as easy as it sounds, not every manufacturer can do it. Just like eating a lot of food doesn’t necessarily make anyone strong, adding a lot of Latex doesn’t necessarily mean a good quality Latex Foam. GeoFoam uses a proprietary formula to make its products thus making its product very unique.

We have had instances of customers coming to us after 18 years and telling us about how the product is still performing well! The difference in the ingredients and formulation is characterizing aspect of GeoFoam.

We have had instances of customers coming to us after 18 years and telling us about how the product is still performing well! The difference in the ingredients and formulation is characterizing aspect of GeoFoam.

It might not make too much sense to spend more for Latex Foam when other substitutes are available at half the price. However, there are two vital aspects that make the purchase of Latex Foam a wise choice.

Usage:

Considering that we spend about one-third of our life on mattresses and a big chunk of the remainder of it on sofas, chairs etc, buying Latex Foam products is more of an investment than an expenditure, giving returns for several years.

Orthopedic Support:

After a hard days work, our bodies deserve to be pampered with luxurious comfort and proper orthopedic support. Latex Foam ensures that the body gets uniform support for fresh ache-free mornings.

Usage:

Considering that we spend about one-third of our life on mattresses and a big chunk of the remainder of it on sofas, chairs etc, buying Latex Foam products is more of an investment than an expenditure, giving returns for several years.

Orthopedic Support:

After a hard days work, our bodies deserve to be pampered with luxurious comfort and proper orthopedic support. Latex Foam ensures that the body gets uniform support for fresh ache-free mornings.